You may have pronounced it wrong, which would make it less likeable, we understand. But if you pronounce it “/fis ynik/”, it then sounds much better, right? It means “Only Son” in French.

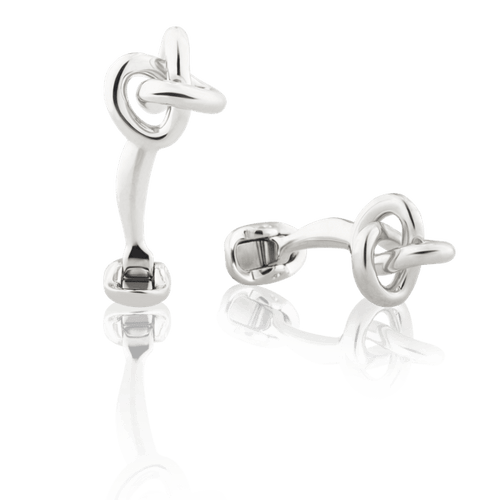

We use Argentium, Argentium is an alloy of silver and germanium that was invented in 1990 by a London Master silversmith.

He created a superior kind of sterling that was more resistant to wear and tarnishing by replacing part of the copper, an element included in Sterling Silver, with Germanium.

HYPO-ALLERGENIC

Argentium is naturally nickel-free and hypoallergenic which makes it the perfect precious metal to wear without fear on a daily basis. Plus, germanium is also an inert metal, which makes Argentium even more hypo-allergenic than traditional sterling silver.

CLEAN

Argentium

Uses 100% recycled silver and guarantees traceability of its raw silver.

Eliminated the need to use toxic chemicals to remove firestains during the process, helping to protect the environment.

Is manufactured more quickly and efficiently, decreasing labor and resource costs and cutting back on manufacturing time.

recycling silver use just 5% of the energy it would take to refine silver from ore, it also eliminates the need for mining, mining waste and mining groundwater pollution.

We can also cast our cufflinks in 18k white gold to provide the unique color and resistance of that other precious metal.

The original design, the model making, the wax model molding, the casting into metal, the painting and the final polish are all done 100% done with care, love and dedication in New York City.

We love creativity and we’d love to help you designing your own unique pair of cufflinks . So don't be shy and contact us, we’ll be in touch shortly to discuss your custom project in details.

Absolutely! We can engrave your initials or private design of the closure back. We can also craft our cufflinks in other precious metals or colors.

Yes, we’ve created a few cufflinks that require a mild safety and caution warning, some of our cufflinks have spikes, some have rough edges. If the occasional wrist is scraped or the odd thread made loose in the pursuit of elegance, those are the breaks. No compromise.

So, you wear them at your own risk and Fils Unique will not be held liable for harm or deterioration done to clothes or persons.

Fils Unique cufflinks are not mass produced; our craftsmen and craftswomen create our cufflinks in limited quantities to ensure quality.

We usually ship the next day if we have the model in stock. If not, we usually ship between five and 15 business days. If you're in a rush, please send us an email, we'll do our best to meet your deadlines.

Your dry cleaner is probably a nice guy, don’t blame him.

It would be so sad to have a lonely, sole cufflink hiding in your drawer, but it can happen to the best of us. And if it does, you can contact us with your order number, and we’ll be happy to offer a replacement individual cufflink at our existing customer preferred rate (50% of the initial pair price).

We’d be surprised, but yes! Please have a look at our return policy.

There is a popular belief that cufflinks are to be offered to someone and in no event bought for oneself. Needless to say, we disagree with the last part, but we encourage gifts.

Just check the “gift” box during checkout and indicate the recipient’s address. We’ll make sure that the price is not indicated in the shipment and that the best care is brought to you gift. We can also include a handwritten card if you wish.

Please contact us. We are dedicated to your satisfaction.

While we bring the utmost care when crafting cufflinks, breakage can happen. Contact us and send us a picture of the broken item.

During a period of 12 months from the purchase date, if the defect is on us, we’ll replace your broken piece for free. If the breakage is not related to a defect, we’ll try to find a solution with you (repair or replacement at your expense).

There is a 12-month guarantee on each pair of cufflinks against defects. The order number will be asked before any return or guarantee coverage.

We ship wherever gentlemen are, worldwide.

If you are dissatisfied with your purchase, for any reason and within 30 days from the delivery date of your order, we’ll be happy to exchange your purchase product against another design of the same value. We don’t reimburse but we’ll issue a voucher for the excess, if any. It goes without saying that, to be eligible for an exchange, the returned item must be in its original condition.

Love them. Wear them.

Our cufflinks are plated with rhodium, which protects them against the ravages of time. While no specific care is required, we encourage you to store them in a dry, cool environment in their original box.

It goes without saying that these small and fine objects don't like heavy pressure, abrasion, and similar rough treatment. It's a delicate thing you know! Treat them like a gentleman does.

Our website is secured by SSL. All payments are processed in PCI compliance (The Payment Card Industry Data Security Standard) with encrypted communications.

We do not, but you can make a gift directly from our website.

It’s important to know and understand what you’re buying. We can tell you that it’s 100% made in New York by truly experienced artisans with the best care and the most passion. If you want to see more and you’re in New York, please contact us for a coffee and a private visit to our atelier’s (subject to availability).

As a former lawyer, I understand you may need some fine print as well. Just to make sure. For you, here’s some bedtime reading:

1. Design

Every new design starts with various sketches and iterations. Nicolas, the founder and President of Fils Unique, designs each of them.

2. CAD 3D Design

The designs are reproduced in 3D using a CAD software. It is the 3D prototype.

3. Model Making - 3D prototype

We 3D print the design in wax with cutting edge technology 3D printer. We use the finest of the finest printers. The wax design that comes out of the printer is the master wax model. It is then reviewed, inspected, scrutinized, examined, analyzed, evaluated (there are other synonyms but you get it).

4. Hand finishing and detailing

We progressively fine-tune the master wax model by hand-filing its surface, carving and engraving additional tiny details, embossing and shaping it until it reaches the perfect level of details, curves or lines and proportions.

5. Silicon Mold Making

A silicon mold is made of the original wax master model. Liquid silicon is poured into a frame containing the master wax model to form, when cured, a silicon mold encapsulating the master wax model.

Silicon molds are quite expensive to make but they are the best possible molds because they allow less than 1% shrinkage. No other material reaches that result. Again, Quality first.

6. Silicon Mold Cutting

When the silicon mold has cured overnight, the silicon mold is cut in a way that provides the best angles and lines. The master wax model (remember step 3 above?) is removed and leaves an empty space that has the shape of the master wax model.

7. Wax Reproductions and Quality Check

The hollow silicon mold can then be used to re-inject hot wax and reproduce the master model afterwards. Each wax reproduction is cleaned by hand and the parting line appearing where the two parts of the mold came together is removed. Each wax reproduction is inspected individually.

The quality of the reproduction wax is generally the most underrated part of the casting process. Any defects in the wax reproduction, like distortion or internal air bubbles, will dramatically affect the end results of the casting.

8. Building a Tree

The wax copy is sprued with a treelike structure of wax.

A “sprue” is the passage through which liquid metal is introduced into a mold. It controls the flow of molten metal into the casting mold and it is thus a very important part of the casting process. If the sprue is not large enough, the molten metal will not flow smoothly into the casting mold and the final model will have defects and irregularities.

Our artisans ensure that each wax is attached with the perfect sprue position (angle, size, thickness).

9. Investment

The treelike structure of wax, with all wax reproduction models attached thereto, is put in place vertically in a steel container (the “flask”). The flask is thereafter filled (“invested”) with investment powder and water that will solidify when heated.

10. Vacuuming the Investment

An air-vacuum process is used to remove all bubbles present in the investment liquid to make sure that there is no hollow space in the investment.

11. Burnout of the Invested Flask

Once our trees are invested and properly air-vacuumed, they are ready to go into our burnout ovens. The invested flask is heated to 1350 F°. The wax present in the investment burns and evaporates during that process leaving a hollow space in the hardened investment.

12. Cooling of the Flask

The flask is then removed from the oven and left aside to cool down.

13. Metal Casting

The cold flask is put into a centrifugal casting machine that uses the weight of the metal and centrifugal force to fill the invested flask. As our models are very detailed and delicate, more force is needed to push the molten metal into the tiny areas of the invested flask.

Too little force and the invested flask doesn’t fill properly. Too much force and you run the risk of blowing the flask.

The idea is to have a steady, constant pressure pushing or pulling the molten metal into the invested flask. Only experienced craftsmen can achieve the perfect balance to cast silver (and other metals) perfectly.

14. Removal of Investment

When the molten metal has solidified and cooled down in the investment, the invested flask is immersed in water. That process entirely removes the investment and leaves only a metal tree (silver, gold, etc.) in the flask.

15. Removal of Casted Pieces from the Metal Tree

We are finally near the end of the process. It is time to carefully remove the castings from the tree. We delicately saw each piece off the tree.

16. Quality control

A first quality control is made at this point to ensure that the casting doesn’t show irregularities or defects and complies with our exacting standards.

17. Assembling

Our jewelers assemble the cufflink with their back. It requires the insertion of a steel spring in-between the cufflink closure back and the cufflink bridge. The steel spring maintains a pressure and a tension so that the closure back stays perfectly in open or close position.

18. Polishing

Our master polisher starts the finishing process and polishes each piece by hand using different steps:

a. Tumbling

The casted cufflinks are put in small batches in a superfine tumbler. Metal tumbling is used to burnish, clean, lightly polish, prepare parts for further finishing, and break off die cast runners. A barrel is filled with mater, lubricants and a medium (small steel pins or silicon pins). The models are placed in the tumbler and then rotated for several hours, very gently, to keep a beautiful finish. The friction with the pins gently removes the outer layer of the casted metal and revels a first shine of the piece.

b. Lapping

Designs with sharp edges require an additional lapping process to remove microscopic scratches on flat surfaces.

c. Micro-Polishing

all traces of filing or sanding marks removed, leaves a “dullish” finish. The surface needs to be refined.

d. Buffing

Metal is brought to a high final shine with the use of the polishing wheel in conjunction with compounds. We then clean the cufflinks and use a chamois for the soft, finishing touch.

19. Painting

Our master enamellers receive the final piece to meticulously apply the various colors onto the design. Our enamellers have decades of experience in the jewelry industry and, more specifically, in the restoration of Fabergé eggs and the hand painting of luxury watches dials. Each design is painted by hand, individually.

Our enamellers use magnifying glasses to pain the tiny details onto each design. A mistake and one has to remove the applied (and cured enamel) and restart from scratch.

Some designs require up to 4 hours of painting on each pair. Again, good things take time to make.

20. Final inspection

Each pair of cufflinks is inspected individually and receives its warranty card only if our standards are met.

Are you still there?

I got all the way through these FAQs. What do I get?

A digital pat on the back. Now we suggest you look around at some beautiful cufflinks.